INTRODUCTION

Rhinoplasty is the surgery indicated for performing aesthetic repairs in the

nose, being functional when it aims to improve respiratory function. Its first

report was described in India, around 500 BC, by Sushruta, considered the father

of plastic surgery, who used various reconstructive techniques on individuals

who had their nose cut off. From this report, the techniques were improving more

and more, and publications about this procedure became common. In the late

1500s, Professor Gaspare Tagliacozzi showed the possibility of nasal

reconstruction using an arm flap; in the mid-1800s, Johann Friedrich

Dieffenbach’s textbook entitled “Operative surgery”

described techniques for reducing the size of the nose. Since then, rhinoplasty

has become increasingly refined based on theoretical and practical training

provided by trained professionals1.

Today, rhinoplasty is a widespread procedure. The evaluation of its results is

based on improving the quality of life and patient satisfaction, which also

depends on factors such as preoperative appearance, expectations and the

doctor-patient relationship, and adequate training2. According to Oni et al. (2011)3, more than half of the residency

program directors evaluated did not feel confident in the residents’

ability to perform rhinoplasty. Much of this is due to the absence of early

exposure and little training time4. Despite this, several techniques were introduced, such as

educational videos, simulations, studies on cadavers and clinical skills

laboratories, but the training base remains the master-apprentice relationship

in surgical procedures, which limits the resident’s development5. It is essential to emphasize

that many alternative educational tools involve high financial costs and

training in patients may face restrictions due to the lack of hospital structure

and resources for the procedure.

Rhinoplasty is considered the most difficult of all cosmetic surgeries, as the

nasal anatomy is highly variable, the procedure must correct form and function,

and the result must meet the expectations of patients6. Therefore, it is necessary to reinforce

surgical learners’ anatomical knowledge and technical skills, using

strategies to increase training time and tools that, preferably, are low-cost

and easily accessible.

OBJECTIVE

This article aims to present a synthetic, novel and practical model for training

in rhinoplasty techniques, developed to be easy to perform and low cost.

METHODS

The study was carried out at the University of Fortaleza (UNIFOR), in

Fortaleza/CE, from September 2020 to December 2020. All ethical aspects of the

research were followed and respected.

Figure 1 - Materials needed for making the model.

Figure 1 - Materials needed for making the model.

To assemble the proposed model, the following materials were used: hot glue,

basin, water, detergent, epoxy putty, spatulas for crafts, nose mold (Carnival

mask), suture threads and white acetic silicone (Figure 1). To color the parts of skin and cartilage, it is necessary

to use dye and a disposable cup and spoon.

The construction of the model was done in three stages

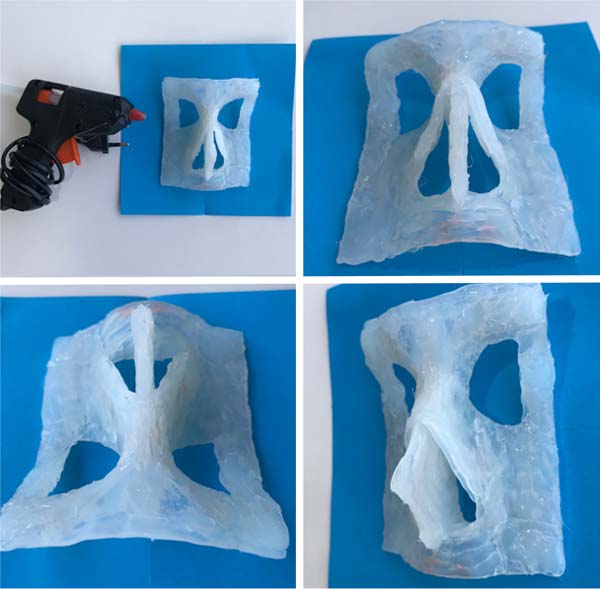

The bone structure of the face:

With hot glue, the structure was made in layers and molded while still hot in

the mask to replicate the bone structures of the face (Figure 2). The first nasal structure to be made was the

septum, followed by the nasal bones themselves.

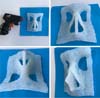

Cartilages

Cartilage construction was made from acetic silicone and an epoxy mass mold

(Figure 3). This mold was

handcrafted, simulating the shape of the upper and lower lateral cartilages

(Figure 4).

The epoxy putty was prepared and allowed to rest for 10 minutes to gain

sufficient consistency to be carved with the craft spatulas. After the mass

had dried, the silicone was poured into the mold and kept until it hardened.

Then, it was removed from the mold and placed in a ventilated place for

complete drying and reduction of the intense odor (Figure 5).

Figure 2 - Bone part made with hot glue.

Figure 2 - Bone part made with hot glue.

Figure 3 - Silicone cartilages and the material for their

manufacture.

Figure 3 - Silicone cartilages and the material for their

manufacture.

Figure 4 - Cartilage molds made of epoxy putty using a craft

spatula.

Figure 4 - Cartilage molds made of epoxy putty using a craft

spatula.

Figure 5 - Inferior lateral cartilages ready.

Figure 5 - Inferior lateral cartilages ready.

Skin

For confection, the dye was added to white acetic silicone in a disposable

container. Then, the mixture was placed in a basin with water and neutral

detergent, being kneaded and rolled by hand until, after a few minutes, a

slight hardening of the mass was observed (Figure 6).

Figure 6 - Ready-made leather and the materials needed for its

construction.

Figure 6 - Ready-made leather and the materials needed for its

construction.

The most consistent silicone was placed in a plastic mold similar to a nose

greased with oil and left to dry. Silicone has a powerful smell and, in

contact with the skin, can cause dry hands. So, protection with gloves and a

mask is essential.

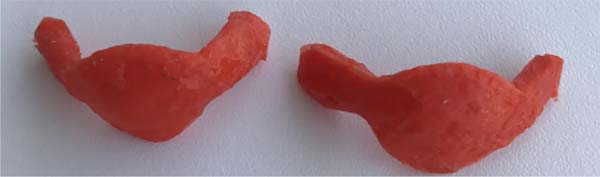

With the cartilages adequately dried, they were fixed to the bone structure

with suture threads (Figure 7). After

that, the skin was used to cover the structure and fixed with a suture to

remain immobile (Figure 8).

The skin was made to provide a better visual appearance to the model, as its

construction will not significantly influence the training period.

Figure 7 - Cartilages attached to the bone structure.

Figure 7 - Cartilages attached to the bone structure.

Figure 8 - Fixed skin covering the structure.

Figure 8 - Fixed skin covering the structure.

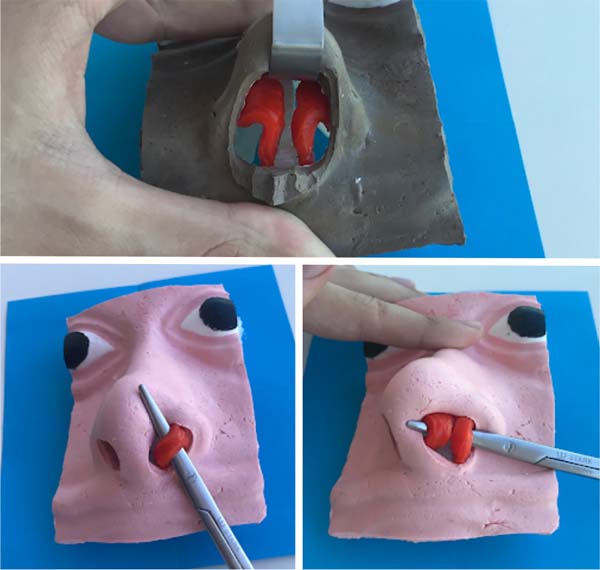

Figure 9 - Cartilage exposure using open and semi-open techniques.

Figure 9 - Cartilage exposure using open and semi-open techniques.

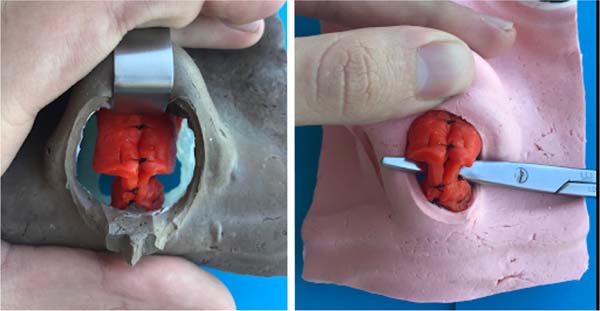

Figure 10 - Completion of the simulation using open and semi-open

techniques.

Figure 10 - Completion of the simulation using open and semi-open

techniques.

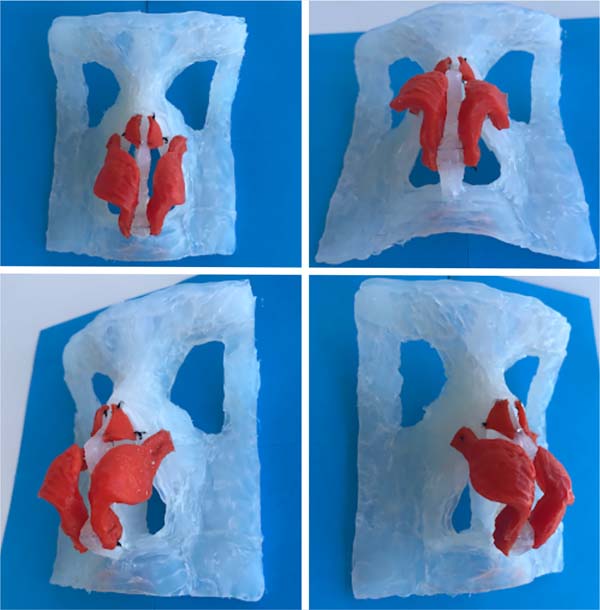

RESULTS

A format similar to the real one was obtained regarding the bone and

cartilaginous structure, as shown in the following images. In addition, color

differentiation between cartilages and nasal bones helps identify each structure

(Figure 9).

The complete structure allows for a very real rhinoplasty simulation, making it

possible to perform a columellar incision for open access and perform maneuvers

on the nasal tip and the back, such as the execution of sutures and the eventual

placement of grafts (Figure 10).

DISCUSSION

Surgical training involves complex practical and theoretical concepts, mainly

related to the surgical technique and its fundamental bases, among which the

development of skills is considered essential. In general, psychomotor skills

are acquired through the observational model, known as “see, do and

repeat”7.

In order to expand skills training beyond operating rooms, it is essential to

develop viable options with as much similarity as possible to the

patient’s tissue. An obvious option would be to study fresh cadavers, but

due to legal obstacles that make it challenging to obtain this material in

Brazil, it is still scarcely available8.

Some experimental models for training surgical skills related to rhinoplasty have

already been published, such as the animal model proposed by Dini et al.

(2012)8, which revealed

great applicability. However, the use of a non-human material also presents

several ethical and bureaucratic complications and does not show complete

similarity. Furthermore, there is a conflict with modern concepts of animal

welfare. Students’ misinformation about ethics and the use of animals,

associated with the obligation to participate in educational activities that use

this teaching method, without the legal right to conscientious objection or the

option of alternatives, have been related as a cause of desensitization

professionals9.

Therefore, the current diversity and complexity of medical-surgical knowledge

require a new direction in teaching through innovative strategies. Several

alternative precepts, also called “substitutives,” have been

exercised to ensure the acquisition of skills, seeking to fulfill the

educational/scientific function without harming the animals. The intention

should be to disseminate, at the ideal time, the knowledge necessary for

adequate professional training, enhancing learning and reducing or abolishing

the use of animals7.

The new synthetic model developed allows for excellent identification of

structures, adequate mobilization of nasal cartilages and easy handling of the

overlying synthetic skin, with consistency, texture and resistance similar to

the real thing. Allows good simulation of some steps of the open and semi-open

techniques of rhinoplasty. The upper and lower lateral cartilages made with

silicone, when sutured, provide a tactile sensation close to that of this

surgical stage in patients. Synthetic skin has a certain elasticity, like what

is observed when performing an open rhinoplasty. It should be noted that this

model has already been used in a hands-on course, at the XV North-Northeast

Congress of Otorhinolaryngology, in August 2019, when several surgeons were able

to learn about the model and realize its similarity to the real one.

In addition to all these technical characteristics of the model, it should be

noted that it does not raise ethical or legal questions that animal models or

training in fresh human corpses inevitably impose due to its synthetic nature.

In addition, another strong point is its low cost, which favors its replication

in medical schools. In this way, it can provide more time and training options

for apprentices in this refined surgery.

On the other hand, the main limitation of this model is that it requires

relatively complex manual skills for its construction. In addition, some steps,

for example, making the bone structure with hot glue, require some abstraction

capacity for construction, as there is no sketch of the three-dimensional shapes

of the face.

Finally, with the presentation of this model, the authors hope to make a relevant

contribution to medical education and, at the same time, encourage the emergence

of new models that improve it, based above all on the creative use of simple,

easily accessible materials and low cost.

CONCLUSION

The exposed model has the potential to positively impact the rhinoplasty learning

process, revealing itself as an accessible and helpful tool for training in the

various stages of the technique of this complex surgery.

REFERENCES

1. Lalwani AK. Otorrinolaringologia, cirurgia de cabeça e

pescoço: diagnóstico e tratamento. 3ª ed. São Paulo:

Artmed; 2013.

2. Esteves SS, Ferreira MG, Almeida JC, Abrunhosa J, Sousa CA.

Evaluation of aesthetic and functional outcomes in rhinoplasty surgery: a

prospective study. Braz J Otorhinolaryngol. 2017

Set/Out;83(5):552-7.

3. Oni G, Ahmad J, Zins JE, Kenkel JM. Cosmetic surgery training in

plastic surgery residency programs in the United States: how have we progressed

in the last three years?. Aesthet Surg J. 2011

Mai;31(4):445-55.

4. Wright EJ, Khosla RK, Howell L, Lee GK. Rhinoplasty education using

a standardized patient encounter. Arch Plast Surg. 2016

Set;43(5):451.

5. Dokuzlar U, Miman MC, Denizoğlu İİ,

Eğrilmez M. Opinions of otorhinolaryngology residents about their

education process. Turkish Arch Otorhinolaryngol. 2010

Set;53(3):100-7.

6. Daniel RK. Aesthetic reconstructive rhinoplasty. In: Daniel RK, ed.

Mastering rhinoplasty. Berlin: Springer Heidelberg; 2010. p.

407-40.

7. Martins Filho EF, Daleck CR, Costa Neto JM. Métodos

alternativos no ensino da técnica cirúrgica veterinária.

São Paulo: Universidade Estadual Paulista (UNESP); 2015.

8. Dini GM, Gonella HA, Fregadolli L, Nunes B, Gozzano R. Novo modelo

animal para treinamento de rinoplastia. Rev Bras Cir Plást.

2012;27(2):201-5.

9. Greif S, Tréz T. A verdadeira face da

experimentação animal: a sua saúde em perigo. Rio de

Janeiro: Sociedade Educacional Fala Bicho; 2000.

1. University of Fortaleza, Fortaleza, CE,

Brazil.

Corresponding author: Arthur Antunes Coimbra

Pinheiro Pacífico, Rua Mariana Furtado Leite 1250, apto 1201

torre 1 - Eng. Luciano Cavalcante, Fortaleza, CE, Brazil, Zip Code 60811-030,

E-mail: arthurh.pacifico@gmail.com

Article received: February 15, 2021.

Article accepted: April 19, 2021.

Conflicts of interest: none.

Institution: University of Fortaleza, Fortaleza, CE, Brazil.